MOLDS FACTORY «PPF» – HIGHEST PRODUCT QUALITY

As a company, we provide our customers with the best quality, cycle time, high process safety and our best services

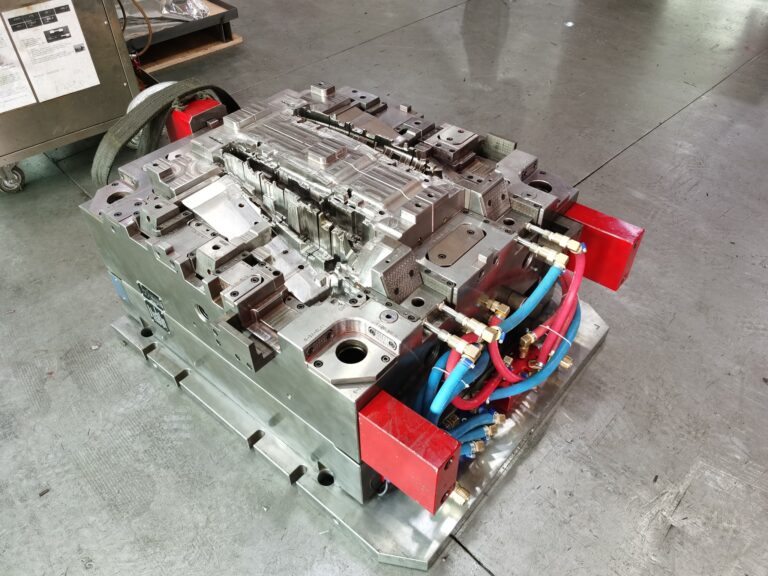

We make the injection molds for production of high-quality stoppers, caps, dispensers and screw caps, and molds for production of PET preforms. We have managed to take the leading position in this industry.

Innovation is the key to success. This is the concept of our team. For more than 20 years, we have been developing and producing state-of-the-art molds thanks to advanced technology and the skills of our specialists.

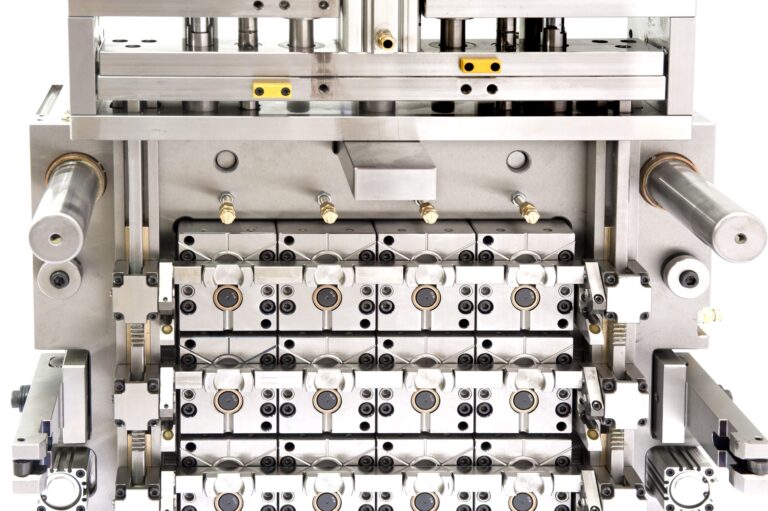

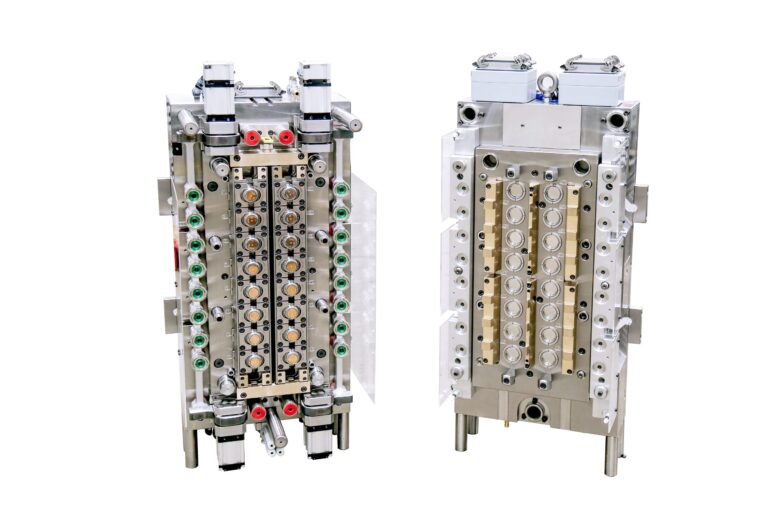

Types of molds

Areas of our competence

Our skills are put to use in the main areas:

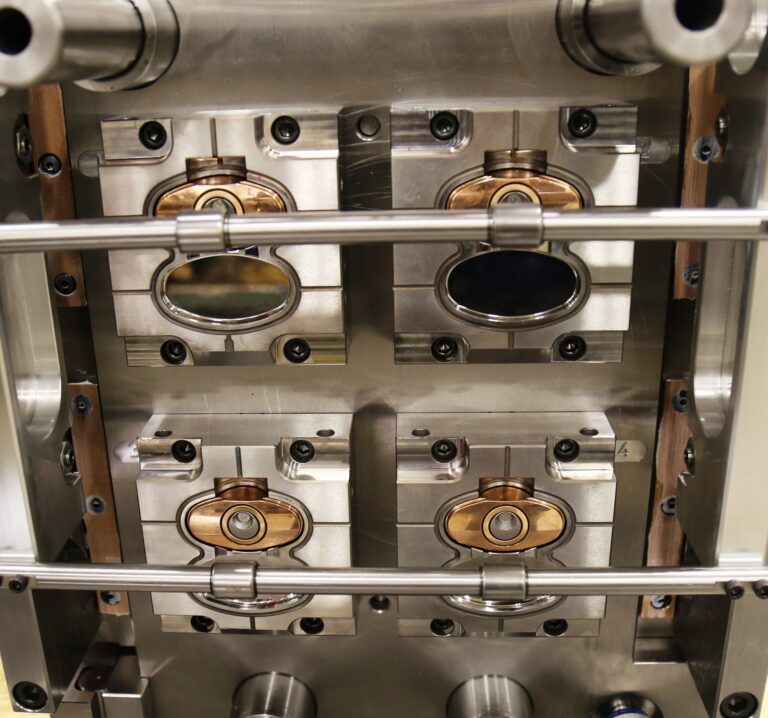

Molds for caps for PET bottles, cosmetics, pet preforms, flip tops, two-component caps for sunflower oil, thin-walled products.

We have a huge experience (since 2000) of production of injection molds for screw caps and lids, stoppers and measuring cups, spoons and plugs.

We produce caps like flip-top, push pull, disk top, IN MOLD CLOSING (IMC), caps for carbonated drinks (CSD) MOLDS, deep screw caps and UNSCREWING CLOSURES, PHARMACEUTICAL MOLDS and different screw caps in assortment. Our closures are designed to meet neck standards DIN 28/410, 24/410, 18/410, Bericap, PCO 1881/1810, BP F and many others.

ADVANTAGES OF ORDERING INJECTION MOLDS FROM US:

- short production time, on average 65 working days and no more than 3 calendar months;

- optimal prices;

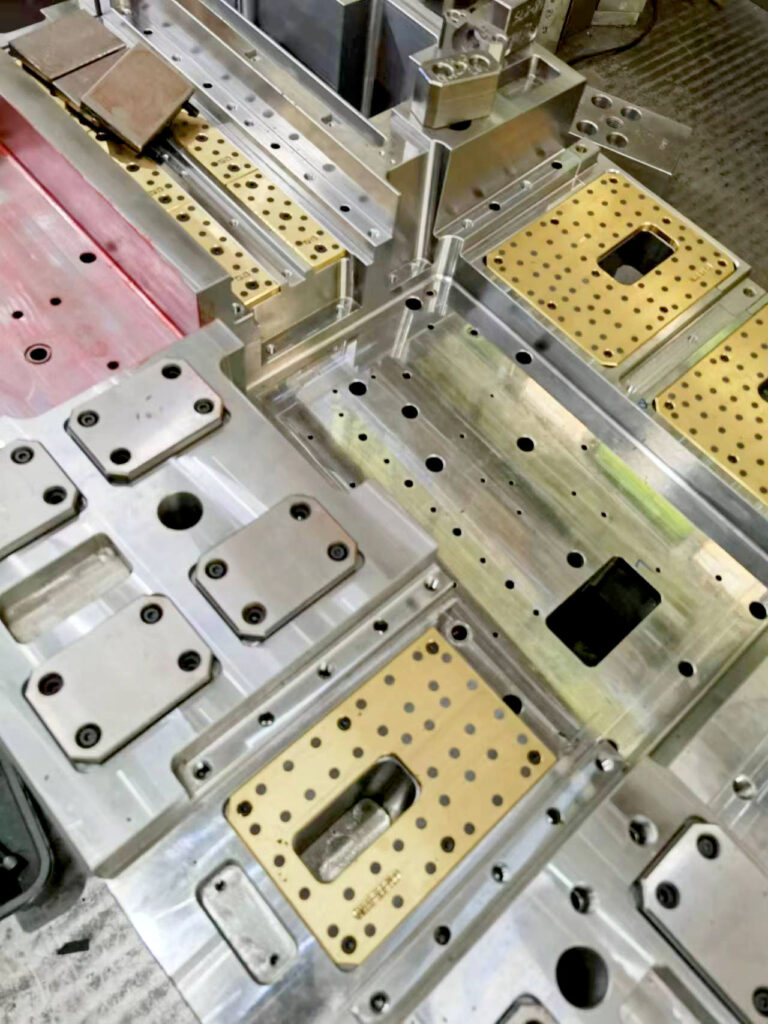

- honest hardness of forming parts 54-56 HRC (Rockwell Hardness Scale C) – this is not a surface nitriding, but the complete hardening of parts, which gives a long service life and a guarantee of reliability;

- guarantee of shots for our molds is from 1 000 000 cycles.

ORDER A FREE CALCULATION

The cost of the mold is calculated by our technical specialists within 1-3 working days.